What Is Sludge Dewatering?

In wastewater treatment, the management of sludge is a critical aspect that often involves the dewatering process. This process holds significant importance in reducing sludge volume, simplifying disposal, and minimizing environmental impact.

Sludge can basically be defined as a mud-like mixture of water and solids that can be created during industrial applications. Sludge can simply be solids in the bottom of a cooling basin, to something as complicated as using chemistry to turn dissolved solids into sediment, and then sediment into larger particles that drop to the bottom of a tank, essentially reducing Total Dissolved Solids (TDS) when treating industrial wastewater.

This sludge then needs to be removed from the system and disposed of. Waste haulers typically charge by weight. Therefore, the more water is removed from the sludge, the cheaper it is to haul off the sludge for disposal.

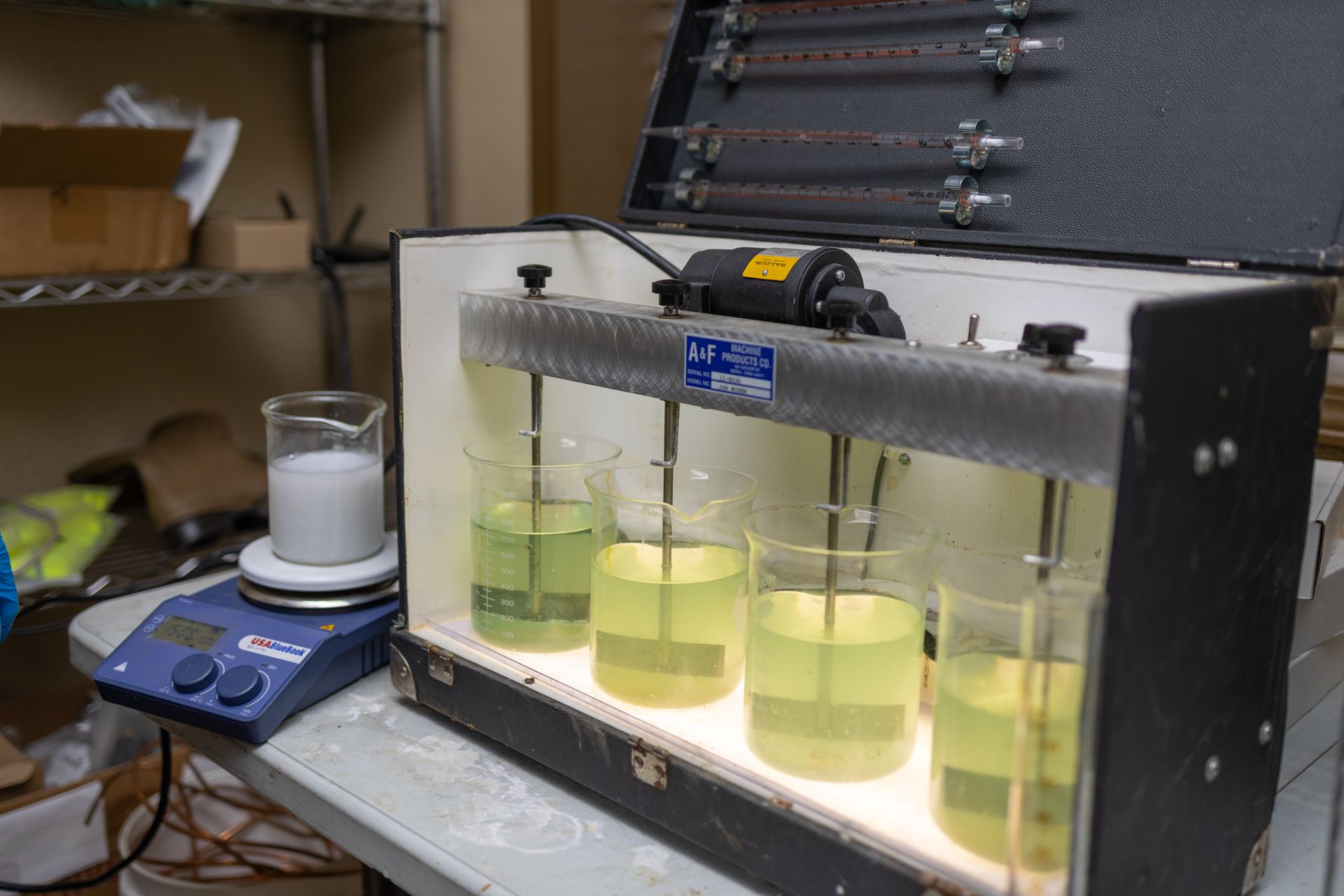

At MAC Water we use specific chemicals called coagulants and flocculants, which is the science behind our MACU-Flocc industrial waster systems.

Understanding The Sludge Dewatering Process

In wastewater treatment, one of the crucial steps in handling sludge is the dewatering process. Sludge dewatering refers to the process of removing moisture from sludge, creating a more concentrated waste product. This is a crucial process that helps reduce the volume of sludge.

Let's look at some common applications of sludge dewatering:

- Municipal Wastewater Treatment: Dewatered sludge is more stable and less odorous, making it easier to handle and dispose of in an environmentally responsible manner. It can be utilized for agricultural purposes, composting, or sent to landfills with reduced environmental impact.

- Industrial Processes: By removing moisture, sludge dewatering improves the overall efficiency of downstream processes, such as incineration or anaerobic digestion. It allows for better utilization of resources and reduces energy consumption.

- Biogas Production: Sludge dewatering contributes to environmental sustainability by minimizing the release of harmful substances into the environment. It helps prevent the contamination of water bodies and reduces the carbon footprint associated with sludge management.

Common Dewatering Equipment

All options depend on up-front capital availability, sludge volume, and operator’s ability. Let's take a closer look at few common pieces of dewatering equipment:

Filter Press

For smaller applications, the traditional approach is a filter press. Plates are pressed together and the dirty water is then pumped into the plates. As the plates get full of sludge, the inlet water pressure is what pushes the water from the sludge. The filter press is full when no more water can be pumped into the filter press. An operator then removes each plate and physically removes the dry sludge into a bin for disposal.

The disadvantages of filter presses are they are expensive, they require the inlet dirty water to be highly fluid or low percent solids, and an operator is required.

Belt Press

Belt presses are commonly used. However, we don't typically recommend them because they require a lot of maintenance. Essentially, solids are placed on belts that constantly turn and compact sludge together. Belt presses are expensive and require lots of maintenance.

Screw Press

Essentially, a screw surrounded by a screen turns and the solids remain in the screw slots that are then compacted (the sludge gets pushed by the screw). This equipment typically uses gravity to dewater. At the end of the screw, the dry sludge fall sin to a disposal drum. The picture in the example is a Russel Finex Liquid Solid Separator.

Advantages of this are there are few moving parts, the equipment is smaller, and an operator is not required all the time.

Automatic Strainer

There are SEVERAL types of auto strainers. The type preferred for sludge dewatering is one where there is a strainer is stationary and a wiper rotates around the strainer. The solids collect on the strainer and the wiper pushes the sludge to the bottom of the strainer cavity while keeping the strainer clean. The width of the strainer cavity can be adjusted to the volume and type of solids in the sludge. The example shown is a Spence Strainer and you can see the motor on top that rotates the wiper. A pneumatic dump valve is opened when there is enough sludge and the water pressure pushes the thick sludge into a disposal bin.

The advantages of this are it is typically less expensive, has only one moving part, and the largest one made can only handle ~100 GPM of sludge production.

Dewatering Bags

Sludge is pumped into a dewatering bag and the water seeps through the bag. This piece of equipment can be used in conjunction with all of the above methods. Dewatering bags are easy to operate and very effective.

Need More Help? Contact MAC Water!

There are so many options and approaches for sludge dewatering it can be confusing. Sometimes it reminds me of the first time I had to buy my own toothpaste and shampoo when I went out on my own. There’s hundreds of choices and a ton of marketing to cypher through. MAC Water Technologies has agreements with competing manufactures which allows us to be non-biased to help our clients make educated decisions. You can get in touch with one of our engineers at info@macwatertech.com or 913-375-3483.

Blog Page Form

We will get back to you as soon as possible.

Please try again later.

Recent Blogs

MACU™ LINE OF PRODUCTS

WHY CHOOSE US

Our Customers Come First

We show up on time, fully prepared

Your time is important to you and your time is important to us.

We respect your schedule and won’t keep you waiting.

We do what we say we’re going to do.

We quote what you ask for in the format you request. After we earn your business, we believe in the value of a quotation. Pricing will not increase after the project has been started.

We finish what we start.

So many businesses employ a “closer” to get your business and then hand it off to someone else. We’re a bit different. Throughout the entire process, you’ll deal with the same person from the design, sale, installation, equipment start-up, to follow-up, we ensure your project stays on budget and meets your expectations.

We say “Please” and “Thank You”.

Many businesses forget that respect is earned. While we build solutions to your water treatment needs, our experts treat you like family. Respecting our customers and providing them with superior service, that is what MAC Water Technologies™ is all about.

PARTNERS

We Provide Parts and Services to Many Recognized Brands in the Industry.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Get in Touch

We’d love to hear from you. Call us now at (913)375-3483 or send a message using the form below to see what MAC Water Technologies can do for YOU!

Footer Form

We will get back to you as soon as possible

Please try again later

Quick Links

Contact - Africa

MAC Water Technologies Africa

Unit 3, 7 Dakota Crescent, Airport Park

Germiston Johannesburg RSA

RSA 1401 South Africa

Phone: +2711 (383) 2119

Email: abel@macwatertech.co.za

All Rights Reserved | MAC Water Technologies, Inc.

Designed and managed by Tekkii Web Solutions