Pharmaceutical

Wastewater & Water Treatment for the Pharmaceutical Industry

We do business with 3 of the top 20 Global Pharmaceutical companies!

The pharmaceutical industry needs someone who understands their industry, not a salesman. USP (United States Pharmacopoeia), WFI (Water for Injection), along with other grades of water need to be understood. More importantly, knowing the differences between them and when to apply them is as important because there are different price points associated with each type.

MAC water Technologies understands water types, when to use them, and the economics behind them. We have no brand allegiances, which allows us the ability to work with every brand on the market, in turn provides us the edge to best serve you and earn referrals.

MAC Water Technologies will provide you with engineered water and wastewater solutions with

several different manufacturer’s products, offering multiple solutions for every budget and long-term goal support. We have designs and equipment in pharmaceutical plants all across the US and internationally.

Pharmaceutical & Drug Manufacturer Services

Quick Links

Contact Us

Sidebar Form

We will get back to you as soon as possible.

Please try again later.

Pharmaceutical & Drug Manufacturer Services

Wastewater Services:

- Discharge permits

- Digesters with Methane reclaim for power generation

- Aeration system technologies

- Cooling tower, boiler Blowdown, and discharge water reclaim

- De-watering technologies

- Sludge increase or reduction strategies

- Land applied sludge enhancements

Installation & Maintenance:

Piping

- Virgin unpigmented

- Type I homopolymer polypropylene high purity piping

- PVDF piping

- Stainless steel piping

All Joining Methods

- Socket fusion

- Butt fusion

- Riontite

- PPro-Seal

- Specialty glue resins

Brands

- GF, Orion, Spears LXT, & More!

Engineered Solutions & Support:

- RO skids with non-proprietary parts

- FDA regulations

- Filtration skids of all kinds; high purity membrane, high volume media, cartridge, and pad filtration

- Multiple disinfection strategies

- Loop design

- Training programs

- Growth strategies

- Consolidation and growth project management with minimal downtime

- De-Ionization Exchange tank Services

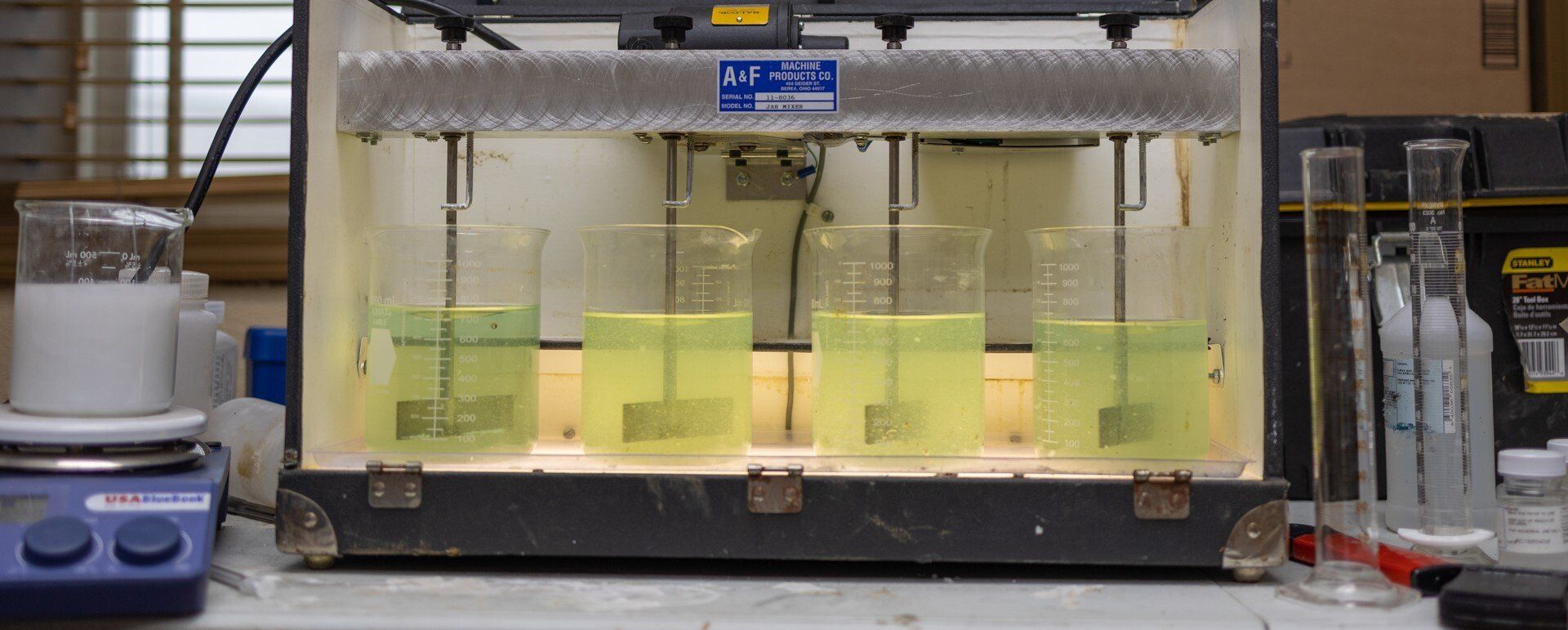

Laboratory Support:

- pH

- TDS

- Temperature

- DO & COD, titrators and other monitoring equipment

- Calibration Solutions

- Chemical Reagents

- Bench Photometers

Markets Served

- Animal Testing

- Microbiology

- Drug Manufacturing

- Parasitology

- Immunology

- Mycology

- Medicine

- Serology

- Virology

- Hematology

- Vaccines

- Infectious Diseases

- Biology Testing

- Crop Science

- Healthcare

- Petri Dishes & Culture Media

Our Top Pharmaceutical Services Include:

-

High Purity Water Treatment Equipment

We have over 100 OEM supplier contracts and 30+ distributor contracts at your disposal. Single components to prefabricated design-build skid systems ready to be integrated into your facility. The most common systems we provide to pharmaceutical clients are water softeners, carbon filtration, chemical pumps, reverse osmosis, Ultraviolet (UV) for TOC and bacteria control, sensors, Deionization (DI), 0.2-micron filtration, and PE polyethylene or stainless steel holding tanks.

REVERSE OSMOSIS

The most common component we provide is Reverse Osmosis (RO) systems. This component is responsible for the operating costs associated with the entire High Purity water system. Different system designs, strategies, membrane choices, and recycle rates are needed to control bacteria growth and DI bed life.

ULTRAVIOLET (UV)

Just like RO systems there are seve2014-12-03 13.25.05ral different options when it comes to UV. The most commonly installed UV brand installed in Pharmaceutical applications is Aquafine. Selecting the right UV product for bacteria control is relatively straight forward. However, Total Organic Carbon (TOC) control is very different and expertise beyond the ability to read a catalog is needed to ensure system sustainability and product safety. Balancing the associated costs between flow rate, filtration, TOC reducing DI resins, and TOC UV equipment is a smarter way to operate this utility.

-

Installation and Maintenance

Piping:

- Virgin unpigmented Type I homopolymer polypropylene high purity piping

- PVDF pipingIMG_0181

- Stainless steel piping

- All brands: GF, Orion, Spears LXT, others

- All joining methods: socket fusion, butt fusion, Riontite, PPro-Seal, specialty glue resins, others

- Virgin resin and media exchange

- Filter changes

- Membrane cleaning and exchanges

- UV bulb, sleeve, and ballast replacement

- PH probe and other sensors

-

Loop Sanitation Strategies

If you are shutting down to sanitizing your loop more than once a year then you have a sanitation strategy problem. Most places, before becoming clients, use a cold sterilant chemical for loop sanitation. This strategy requires a long downtime, is labor intensive, and uses large volumes of expensively treated water. While this may be the best solution, alternatives like ozone and Hydroxyl Radicals, are proving to be much more cost effective because their associated costs have steadily declined due to technology maturation.

The advantages of these alternatives is the speed at which loop sanitation occurs, which is typically just a few hours, plus there is no waste of expensively treated water and even the DI beds can be sanitized. Additionally, loop sanitation can take place automatically in the evening or on weekends with minimal supervision.

In the long run, discovering where the bacteria is growing, eliminating dead legs, and adjusting flow velocities typically proves to be the most cost effective sanitation strategy.

-

Engineering Design

We work with engineering firms and end users to design their high purity water systems.

- We do not replace engineering firms, we will enhance them. We are specifically focused on High Purity water system, not the rest of the building. High Purity water system designs require a very specific and focused set of skills and expertise.

- Sanitation – Most engineering firms understand sanitation but not how to prevent the NEED for sanitation.

- Current Market Prices – Engineering firms are not connected to the detailed marketplace like the difference between homogeneous piping verse stainless steel piping costs TODAY. They have a book that provides them standard cost guidelines, even though we are all aware of the fluctuating costs of steel. These things need to be understood if you are to make an educated decision about pipe materials.

- Equipment Specification – Do engineering firms know that there are different brands other than Evoqua (Siemens), for example? Evoqua is a fine brand and we can show you those options but, we all know that good equipment in the wrong application is still very expensive.

- Looking Ahead – Designing for growth is also an important element in your facilities vision. The need to buy all new equipment for your potential upcoming expansion in a few years should be considered now to save money and future down-time.

-

Engineering Support

Our engineering services pay for themselves and we work at an hourly rate only when needed. Most of our clients have an existing water treatment company but still ask themselves:

- What they are putting into my system

- Why they are using those filters

- Why are they using those chemicals

- Why are they sanitizing, again

- If their pricing is competitive

- How to read their invoices

We have found that most clients when they start with us do not even understand the details of the invoices they are paying. We answer these questions and enable you to hold your contractor accountable. If your system was designed and installed correctly it really is not necessary to have a technicians van on your property every month.

The most common used engineering service we provide is data analysis. I am sure you take daily readings on your equipment. I am also, reasonably, sure no one ever looks at the data. We will analyze the data and interpret it for you. With the interpreted data we can know:

- When a pump is about to go out

- If and when a valve was adjusted incorrectly

- If and when a UV bulb has burnt out

- If the chemical injection pump is about to break or needs to be adjusted.

The ROI here, and most obvious way this service pays for itself is you will know if your system is getting dirty, why it is getting dirty, what adjustments need to be made to reduce the speed of it getting dirty, and let you know when to schedule a cleaning. Doing this makes your water systems sustainable and predictable. Predictable is good when budgets come into play.

All of these services can be provided to you anywhere in the World.

-

De-Ionization Exchange Tank Service

Our competitors resin is typically regenerated in bulk with the rest of the market’s resin that they serve. That resin’s last job could have been in waste water, plating, city water, or High Purity water. All of those resins are mixed together in the bulk regenerating process tank. Our resin is ONLY provided to high purity water applications. This ensures consistent water quality and volumes treated.

- We only use the highest purity resins with no inert or chemical by products

- Every tank is shipped dry and air tight

- Extra bottles can be stored in your facility

- You will never again leave a message on an 1-800 number or wait for a technician

We can also:

- Reserve specific resin types and bottles for your facility only

- You get the same resin and tanks every time

- You won’t share resin with another company

TESTIMONIALS

A Referral Based Company

We are a referral based company and being so we must look after our customers first. If we do not do this, we will not receive any referrals, and if we do not receive referrals, we go out of business. By operating for the customer this way, and sticking to our values, we have quickly gained a world-wide customer base and expanded our markets.

"I turn to MAC Water Technologies when I have a problem with any of the 14 small RO/DI Systems that serve the labs in our bioscience business incubator. They respond quickly and their services are a good value."

- Gary Michael

P.E. Facilities Project Manager

"It is a pleasure working with MAC Water Technologies because they are always well prepared before they call and I know they will properly apply our equipment. It is clear they understand fluid pumping techniques."

- Grundfos

Pumps Inc.

"We have used MAC Water on two major projects in our operation. Both improvements are successful in return on investment and more importantly made our company environmentally sound."

- Rick Salyer

Inficon EDC.

"Honesty and integrity are why I use and recommend MAC Water to my clients. They always explain their equipment recommendations which makes me feel like I am getting the best solution every time."

- Larson

Binkley

MACU™ LINE OF PRODUCTS

WHY CHOOSE US

Our Customers Come First

We show up on time, fully prepared

Your time is important to you and your time is important to us.

We respect your schedule and won’t keep you waiting.

We do what we say we’re going to do.

We quote what you ask for in the format you request. After we earn your business, we believe in the value of a quotation. Pricing will not increase after the project has been started.

We finish what we start.

So many businesses employ a “closer” to get your business and then hand it off to someone else. We’re a bit different. Throughout the entire process, you’ll deal with the same person from the design, sale, installation, equipment start-up, to follow-up, we ensure your project stays on budget and meets your expectations.

We say “Please” and “Thank You”.

Many businesses forget that respect is earned. While we build solutions to your water treatment needs, our experts treat you like family. Respecting our customers and providing them with superior service, that is what MAC Water Technologies™ is all about.

PARTNERS

We Provide Parts and Services to Many Recognized Brands in the Industry.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Get in Touch

We’d love to hear from you. Call us now at (913)375-3483 or send a message using the form below to see what MAC Water Technologies can do for YOU!

Footer Form

We will get back to you as soon as possible

Please try again later

Quick Links

Contact - Africa

MAC Water Technologies Africa

Unit 3, 7 Dakota Crescent, Airport Park

Germiston Johannesburg RSA

RSA 1401 South Africa

Phone: +2711 (383) 2119

Email: abel@macwatertech.co.za

All Rights Reserved | MAC Water Technologies, Inc.

Designed and managed by Tekkii Web Solutions