What is Defoamer used for and how does it Work?

Foam can be a pesky problem in wastewater treatment, causing operational inefficiencies, equipment damage, and compliance issues. If you've ever wondered what defoamers are and why they are used, you've come to the right place. Our team at MAC Water has been receiving a lot of questions lately about defoamers and want to shed some light on when using a defoamer may be necessary and how defoamers work.

Understanding the Challenges of Foam in Wastewater Treatment

Wastewater treatment plants often encounter foam due to a variety of factors, such as the presence of surfactants, organic matter, or agitation in the treatment process. Foam not only hinders the smooth operation of equipment but also reduces the effective capacity of treatment units. Excessive foam can overflow from tanks, interfere with the separation of solids and liquids, and cause disruptions throughout the treatment system.

Foam can create difficulties in clarifiers, aeration tanks, and even in final effluent discharge. It can impair the accuracy of level measurements, lead to inconsistent chemical dosing, and compromise the efficiency of biological processes. Other issues include:

- Pumps can lose prime

- Cause cavitation in pumps

- Cause sensors to not read correctly

- Make a HUGE mess by foaming over tanks and basins

- Cause odor

- Cause solids to float

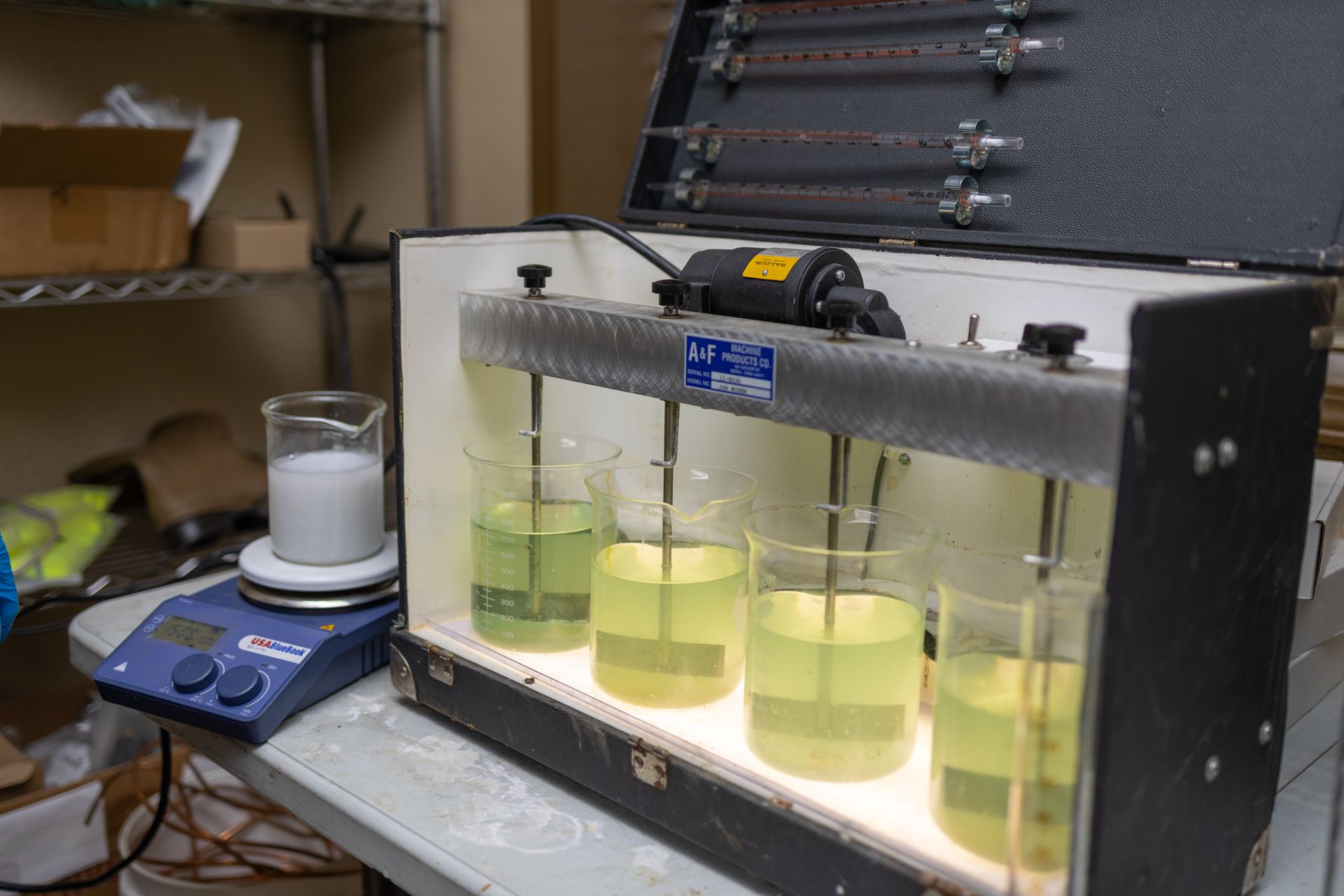

How Do Defoamers Work?

Defoamers, as the name suggests, are chemicals designed to eliminate or prevent foam formation. They are formulated to break down foam bubbles and reduce surface tension, ultimately suppressing foam formation and allowing for smoother operation in water treatment systems.

Defoamers work by either destabilizing foam bubbles, preventing their formation, or collapsing existing foam. They contain active ingredients that have defoaming properties, such as silicone compounds or mineral oils. When added to the foam-affected area, defoamers quickly spread over the surface, disrupting the foam structure and causing the bubbles to burst.

There are many different types of defoamers out there, but the two main types we use at MAC Water are:

- Silicone based defoamers for cooling systems and general applications.

- Polyglycol high temperature defoamers for boilers.

It's important to note that defoamers are typically designed to work on specific types of foam. Factors such as pH, temperature, and chemical composition can influence the effectiveness of a defoamer. Therefore, it is crucial to select the appropriate defoamer that matches the specific foam-related challenges in your treatment processes.

Common Applications of Defoamers

Defoamers find extensive use in a wide range of industries and processes where foam control is essential:

Wastewater Treatment Plants

One of the primary applications of defoamers is in wastewater treatment plants. These facilities often encounter foam in various treatment stages, including aeration tanks, clarifiers, and sludge processing units.

Industrial Processes

Defoamers are widely used in various industrial processes where foam can hinder productivity and compromise product quality. Industries such as chemical manufacturing, pharmaceuticals, textiles, and oil refining often rely on defoamers to control foam formation.

Food and Beverage Production

In the food and beverage industry, foam can be a common occurrence during various production processes, such as fermentation, mixing, and bottling.

Paper and Pulp Industry

Foam is a significant concern in the paper and pulp industry, where it can interfere with the efficiency of pulping, paper machine operations, and wastewater treatment associated with these processes.

Cooling Towers

Cooling towers are essential in many industries for heat dissipation and maintaining optimal process temperatures. However, the recirculating water in cooling towers is prone to foaming, which can impair heat transfer and reduce cooling efficiency.

Need Help With Your Defoaming Process?

If you should need assistance in determining what defoamer is right for you please contact us. Our team of engineers is here to help guide you through the wild world of defoamers. Remember, a little goes a long way with chemical defoamers!

Blog Page Form

We will get back to you as soon as possible.

Please try again later.

Recent Blogs

MACU™ LINE OF PRODUCTS

WHY CHOOSE US

Our Customers Come First

We show up on time, fully prepared

Your time is important to you and your time is important to us.

We respect your schedule and won’t keep you waiting.

We do what we say we’re going to do.

We quote what you ask for in the format you request. After we earn your business, we believe in the value of a quotation. Pricing will not increase after the project has been started.

We finish what we start.

So many businesses employ a “closer” to get your business and then hand it off to someone else. We’re a bit different. Throughout the entire process, you’ll deal with the same person from the design, sale, installation, equipment start-up, to follow-up, we ensure your project stays on budget and meets your expectations.

We say “Please” and “Thank You”.

Many businesses forget that respect is earned. While we build solutions to your water treatment needs, our experts treat you like family. Respecting our customers and providing them with superior service, that is what MAC Water Technologies™ is all about.

PARTNERS

We Provide Parts and Services to Many Recognized Brands in the Industry.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Get in Touch

We’d love to hear from you. Call us now at (913)375-3483 or send a message using the form below to see what MAC Water Technologies can do for YOU!

Footer Form

We will get back to you as soon as possible

Please try again later

Quick Links

Contact - Africa

MAC Water Technologies Africa

Unit 3, 7 Dakota Crescent, Airport Park

Germiston Johannesburg RSA

RSA 1401 South Africa

Phone: +2711 (383) 2119

Email: abel@macwatertech.co.za

All Rights Reserved | MAC Water Technologies, Inc.

Designed and managed by Tekkii Web Solutions